WELCOME TO

SVETS & MEKANO AB

Subcontractor in laser cutting, pressbraking, eccentric press, machining, manuell welding,

robot welding, paint shop with blasting/wet painting and assembly

FACTS ABOUT SVETS & MEKANO AB

Briefly about our company

At present we are 40 employees and will generate an annual turnover of approximately 82 million Swedish kronor.

Equally, as we manufacture a simple sheet metal, we can undertake to manufacture and finalize a finished, larger product in several series.

We work with sheet metal products from about 2 mm up to about 30 mm. The volumes are around 3-15 mm.

Our series sizes range from 1 unit up to about 10-15,000 details per year.

Surface treatment

MORE INFO

We have our own surface treatment department complete with laundry, blaster, and wet lacquer.

The plant is also suitable for painting with epoxy and polyurethane paints.

Drying takes place in our two drying ovens.

Manual welding

MORE INFO

Machine machining, assembly, and construction

MORE INFO

Machine machining is carried out with manual drilling and machining in controlled machines. In our own design department work with product and fixture construction takes place. In the assembly department, the finished parts are assembled and the finished product is completed.

Robot welding

MORE INFO

Robot welding is a growing branch, where annual figures and year details today do not have to be more than about 100 details/year due to welding times and other factors. In our machinery, we have three Motorman welding robots.

Plate production and plasma/laser cutting

MORE INFO

SPECIALIST IN TURNKEY ADVANCED SHEET WORKS

Svets & Mekano is certified according to ISO 9001 (quality), ISO 14001 (environment) and ISO 3834-2 (welding). We carry out skilled sheet metal work and work actively with you as a customer in design and product customization, all to meet your special requirements and wishes.

EXAMPLES OF PRODUCTS WE MANUFACTURE

We manufacture hydraulic and fuel tanks of different sizes. Volume levels range from about 1 liter up to 3600 liters. Today, we produce about 2500 tanks a year for different customers. Most of them are fitted with couplings, level welds, etc. We have special equipment for cleaning hydraulic tanks, the purity requirements are high. We design and manufacture cooling hoods for electric motors/generators of the larger stroke. We cooperate with Coiltech in Söderköping. The products are usually delivered fully assembled including electrical connection.

LIST OF MACHINERY

Lasercutting

MORE INFO

Trumpf TLC 3030 with 3200 W laser.

Complete with automated driving handling equipment.

3000 * 1500 * 20 mm, in SS 2333 Tmax = 12 mm

Plasmacutting

MORE INFO

MetalMaster 6020 with Plasma Hypertherm HPR 260 Amp

Max plate size 6000 * 2000 * 40 mm

Press brakes

MORE INFO

Ursviken Optiflex with bending aid

200 tonnes hydraulic. 6-axis L = 3500 mm

Beyler

200 tons hydraulic, CNC controlled. 6 axes. L = 3100 mm

Darley

200 tons hydraulic, CNC controlled. L = 4300 mm

Metal Shears

MORE INFO

Tmax=10 mm, L=3100 mm.

Excenterpress

MORE INFO

125 tones. Edge 1000 * 650 mm.

Aros

63 tones. Edge 600 * 450 mm.

Mätmaskin

MORE INFO

Roll Bending

MORE INFO

Tmax=10 mm, L=2000 mm.

Iron cutting

MORE INFO

max dia= 400 mm

Bandsåg MEP 280 SXI with thread

max dia = 150 mm

Processing / Drilling / Tapping

MORE INFO

Table 1800 * 900 mm. 24 tools.

Daewoo ACE-H400 P with steering system Fanuc 18MC with 2 400 * 400 palettes.

Work area X 600, Y 560, Z 560 mm. Max load 400 kg.

Radial Gsp

Arm length 1300 mm.

Johnford VMC-1624 with steering system Heidenheim TNC 430.

Table 1800 * 900 mm. 24 tools.

Niagata SPN 50 with 2 pallets 500 * 500 with working area 720 * 720 * 720 and steering system Fanuc 16 M. Max load 600 kg. 60 vtg.

Radial KMR-700 DS

Arm length 700 mm..

Welding

MORE INFO

Max turn radius 750 mm, load / side 500 kg.

Length between fixtures = 2050 mm.

Including search / follow-up.

1 welding robot station MOTOMAN UP-20-6

with manipulator VMF-750S5X.

Max turn radius 1100 mm, load / side 750 kg.

Length between fixtures = 3150 mm.

Including search / follow-up.

Phase Pullmax X97 25-55 °

9 welding sites equipped with MIGATRONIC welding.

350 – 500 Amp. All water-cooled. Calibrated.

All workplaces with lifting tables and swivel cranes.

Welding mode switch ErgoControll, programmable.

max load 1000 kg, arm length = 1500 mm.

Tigsvets MILLER XMT 300

Bultsvets Esab Alpha 850

max diameter 120 mm.

Point welding 30 kVA with guard.

CAD/Konstruktion/Beredning

MER INFORMATION

2 st arbetsplatser med Ironcad

Mounting

MORE INFO

3 complete workplaces for cleaning and installing hydraulic tanks.

2 complete workplaces for various mounting.

Surface treatment

MORE INFO

max goods L = 3000, H = 1500, B = 1500 mm.

Blaster room with sand recycling/purification

surface area 8000 * 6000 mm.

Painting room, (Figure 2) with air purificatio

surface area 8000 * 7000 mm.

High pressure pumps / low pressure pumps

Kiln

L = 4000, H = 2700, B = 3900 mm.

Kiln

L = 4000, H = 3700, B = 3500 mm.

Cooling rooms

surface area 12000 * 6000 mm.

OPEN JOBS

We have an incredibly good order intake so we are looking for more staff that can start soon as possible.

Are you interested email us at personal@svetsmek.eu

OUR TEAM – SVETS & MEKANO AB

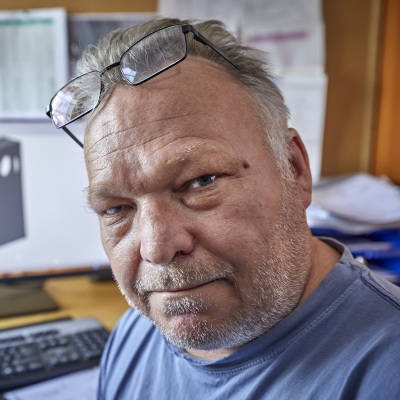

Göran Johansson

Production manager /Partner

+46 (0) 10 – 450 99 05

goran.johansson@svetsmek.eu

Luka Sundic

Construction/Project

+46 (0) 10 – 450 99 21

luca.sundic@svetsmek.eu

Maria Strömberg

Purchase,

+46 (0) 10 – 450 99 12

maria.stromberg@svetsmek.eu

Patrik Johansson

Manufactory manager

+46 (0) 10 – 450 99 09

patrik.johansson@svetsmek.eu

Pär-Anders Hjerpe

Staff , Admin,Management /Partner

+46 (0) 10 – 450 99 17

par-anders.hjerpe@svetsmek.eu

Bengt-Erik Davidsson

Admin/IT/Managament/Partner

+46 (0) 10 – 450 99 11

bengt-erik.davidsson@svetsmek.eu

Klas-Erik Svensson

Construction/Project

+46 (0) 10 – 450 99 07

klas-erik.svensson@svetsmek.eu

Benny Pelz

Welding responsible

+46 (0) 10 – 450 99 25

benny.pelz@svetsmek.eu

Tuomo Piri

Construction/Project

+46 (0) 10 – 450 99 00

tuomo.piri@svetsmek.eu

Sale

Sales questions

sales@svetsmek.eu

Emma Hjerpe

Accounts payable

+46 (0) 10 – 450 99 00

ekonomi@svetsmek.eu

Sandra Färm

Delivery responible

+46 (0) 10 – 450 99 30

sandra.farm@svetsmek.eu

CONTACT US

Adress:

Svets & Mekano Produktion AB

Olvägen 9 SE 342 50 Vislanda

Sverige